EBAM Solutions for Evidence-Based Asset Management is a game-changer for organizations looking to optimize their asset management practices.

By leveraging EBAM, companies can reduce maintenance costs by up to 30% and increase asset utilization by 25%. This is achieved through the implementation of data-driven maintenance strategies and the reduction of unnecessary maintenance activities.

EBAM enables organizations to make informed decisions by providing a clear and accurate picture of their assets' condition and performance. This is made possible through the use of advanced data analytics and asset monitoring technologies.

By adopting EBAM solutions, organizations can improve their overall asset management efficiency and effectiveness, leading to significant cost savings and improved productivity.

Expand your knowledge: What Is Financial Asset Management Systems

Benefits and Features

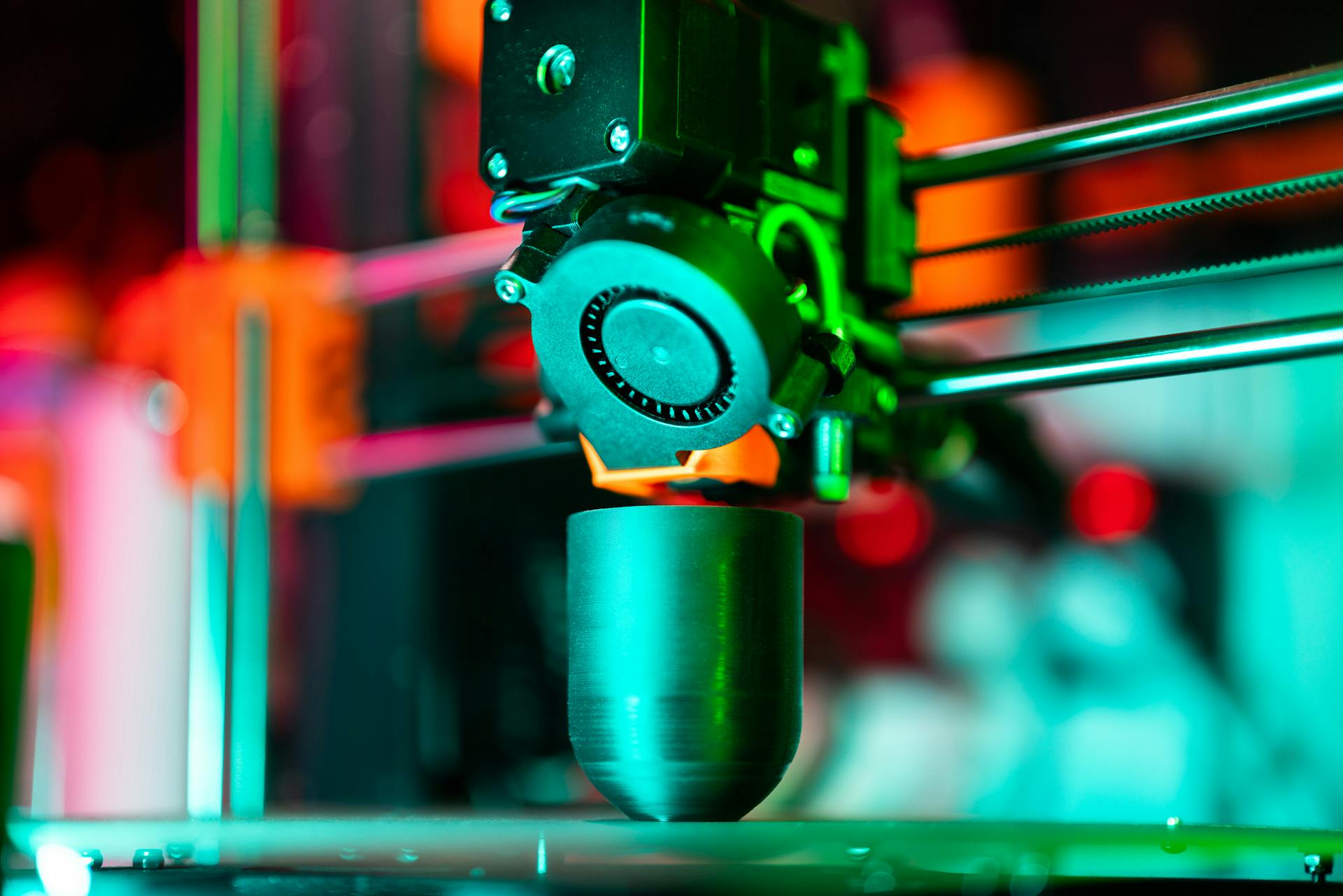

EBAM offers a wide range of material options for large-scale metal applications, making it an ideal choice for industries that require high-quality metal parts.

Reduces material costs, lead times, and machining times by as much as 80% compared to conventional manufacturing methods.

For more insights, see: I M B Bank Share Price Today

One of the key benefits of EBAM is its ability to produce large metal parts quickly and efficiently, with some parts taking as little as 12 minutes to print.

With EBAM's pure vacuum environment, the process doesn't require the use of Argon or any inert gas for part shielding, reducing costs and increasing efficiency.

EBAM's exclusive dual wirefeed process allows you to feed two different metal alloys into a single melt pool to create parts made of custom alloys.

Here are some of the key features of EBAM:

- Reduces material costs, lead times, and machining times (as much as 80%) vs. conventional manufacturing

- The fastest, most cost-effective Additive Manufacturing process in the market for producing large metal parts

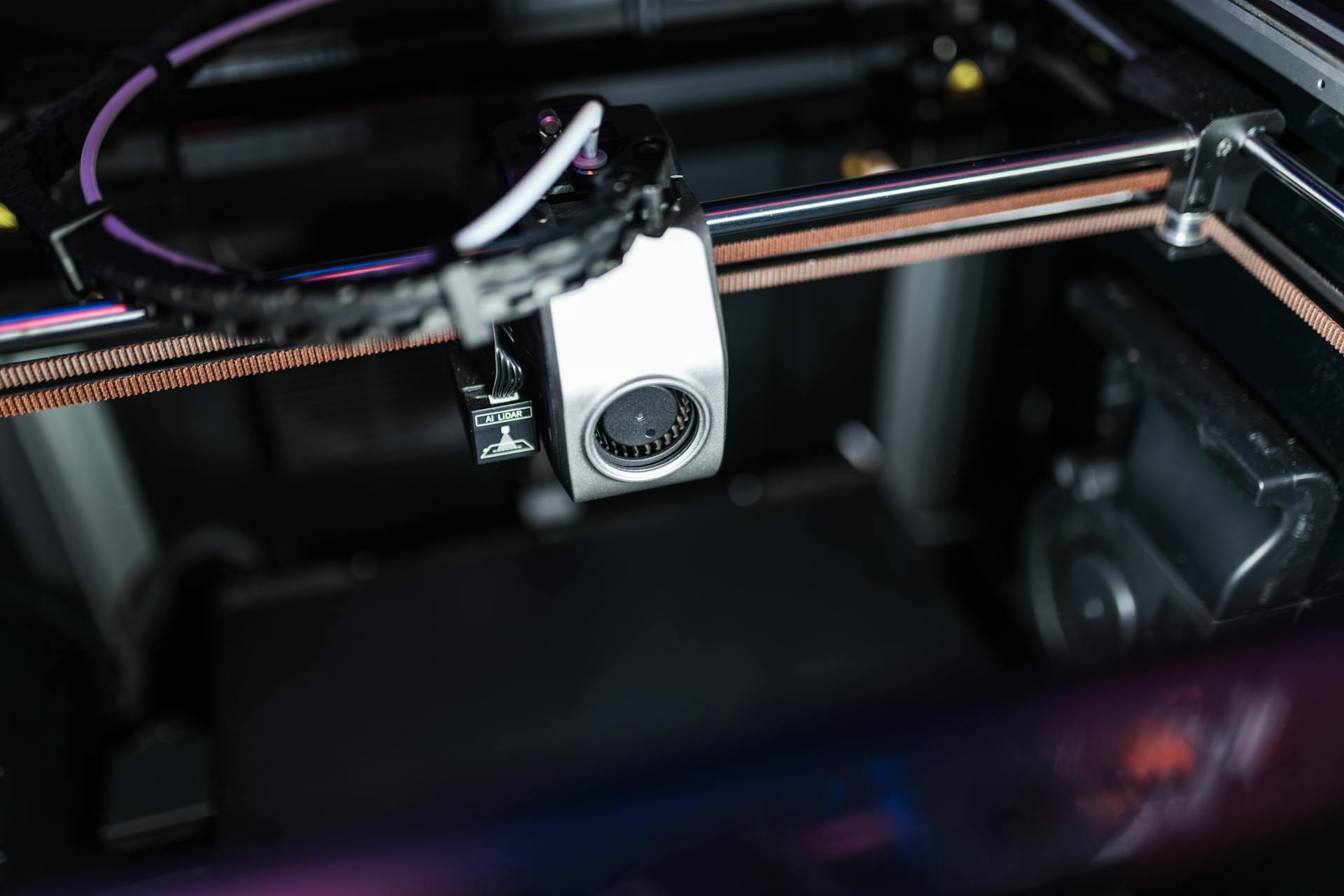

- IRISS Closed-Loop Control Technology ensures process repeatability and traceability (real-time adaptive control)

- The widest range of material options for large-scale metal applications

- Start 3D printing parts in as little as 12 minutes

EBAM's high deposition rate (HDR) allows for gross deposition rates ranging from 7 to 40 lbs. (3.18 to 18.14 kg) of metal per hour, depending on the selected material and part features.

The EBAM dual wirefeed system also allows you to change the mixture ratio of the two materials, depending on the features of the part you are building, to create "graded" parts or structures.

Technical Specifications

Sciaky's EBAM machines can produce parts and structures up to 19 ft. x 4 ft. x 4 ft. in size, or round parts up to 8 ft. in diameter.

The EBAM 68 System has a chamber dimension of 68” x 68” x 110”, with a work envelope of 28” wide x 25” deep x 63” high, and a nominal part envelope of 64” wide x 25” deep x 63” high.

The machine features high efficiency pumping with a chamber hard vacuum of 1 x 10-4 Torr, and a power level up to 42 kW with 60 kV.

The 68

The 68" EBAM System is a significant piece of equipment for large-scale metal additive manufacturing. It has a chamber dimension of 68” (1727 mm) x 68” (1727 mm) x 110” (2794 mm).

The work envelope of the system is quite spacious, measuring 28” (711 mm) wide x 25” (635 mm) deep x 63” (1600 mm) high. This allows for the creation of large metal structures.

The nominal part envelope is slightly smaller, measuring 64” (1625 mm) wide x 25” (635 mm) deep x 63” (1600 mm) high. This is still a significant size range for metal additive manufacturing.

The EBAM 68 System features high efficiency pumping, achieving a chamber hard vacuum of 1 x 10-4 Torr. This is crucial for the additive manufacturing process.

The system's power level is up to 42 kW, with a voltage of 60 kV. This level of power is necessary for the electron beam additive manufacturing process.

Here's a summary of the EBAM 68 System's technical specifications:

The EBAM 68 System also features an internal boom-mounted gun with high-resolution optics and a servo gun tilt axis, as well as X, Y & Z servo axes with multiple part positioner options.

Particulate Size Selection

The E-BAM can be used with various particulate size selections, including TSP, PM10, PM2.5, and PM1 inlets.

Each of these inlets is designed to capture specific particle sizes, with the PM10 inlet removing particles larger than 10 microns.

The PM10 inlet is not affected by wind speed or wind direction, making it a reliable option for size selective concentration measurements.

The E-BAM's integral flow meter, pressure sensor, and ambient temperature sensor work together to maintain flow dependent cut points in the size selective inlets.

For PM2.5 or PM1 inlets, secondary size selection is made using a second downstream inlet.

Intriguing read: Atm Machine Size Specifications

Digital, Analog & Alarm Outputs

The E-BAM provides continuous digital and analog outputs. This means you'll have a steady stream of data to work with.

The analog output is quite versatile, with several full-scale voltage options available. This flexibility can be a big plus in certain applications.

A single channel contact closure alarm relay output is available for alerting you to unspecified errors. This could be something like a broken tape or sensor failure, or even a flow failure.

Here's an interesting read: Credit Suisse Failure

About Accuracy

Real-time accurate measurement of ambient fine particulate matter has been a long-standing goal for environmental regulators and health professionals.

The E-BAM, developed by Met One Instruments Powered by Acoem, is reliable and easy to operate.

Results are automatically reported in near real time, eliminating the need for high levels of human intervention.

Sampling occurs under true ambient conditions, making it easy to detect semi-volatile organic compounds and nitrates.

This approach avoids under-measurement of particulates, producing comparable results to the manual reference method.

Roadmap and Formats

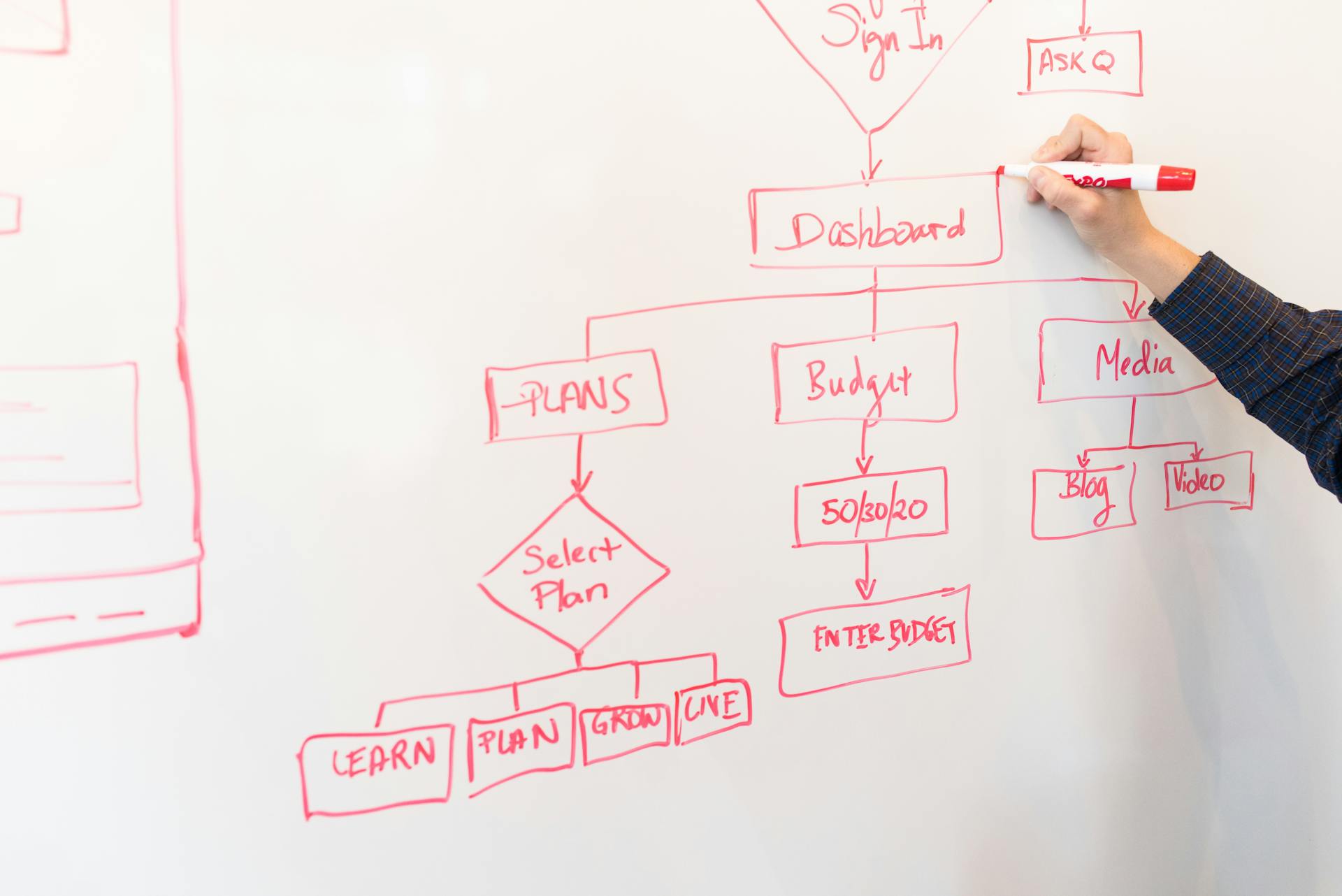

Multibanking and standardization are key components of our solution, allowing you to manage and control all domestic and international banking relationships.

Our system is built around the eBAM standard, which enables automatic, standardized, and centralized account maintenance. This standard has been developed by the interbanking community, specifically SWIFT.

The eBAM standard introduces the "acmt" formats, which RBI adheres to. These formats are currently live and include the Account Report (acmt.013/acmt.014).

We're rolling out features in a phased plan, with a focus on improving cash management.

A fresh viewpoint: Bank Services Billing Standard

Industrial Metal 3D Printers

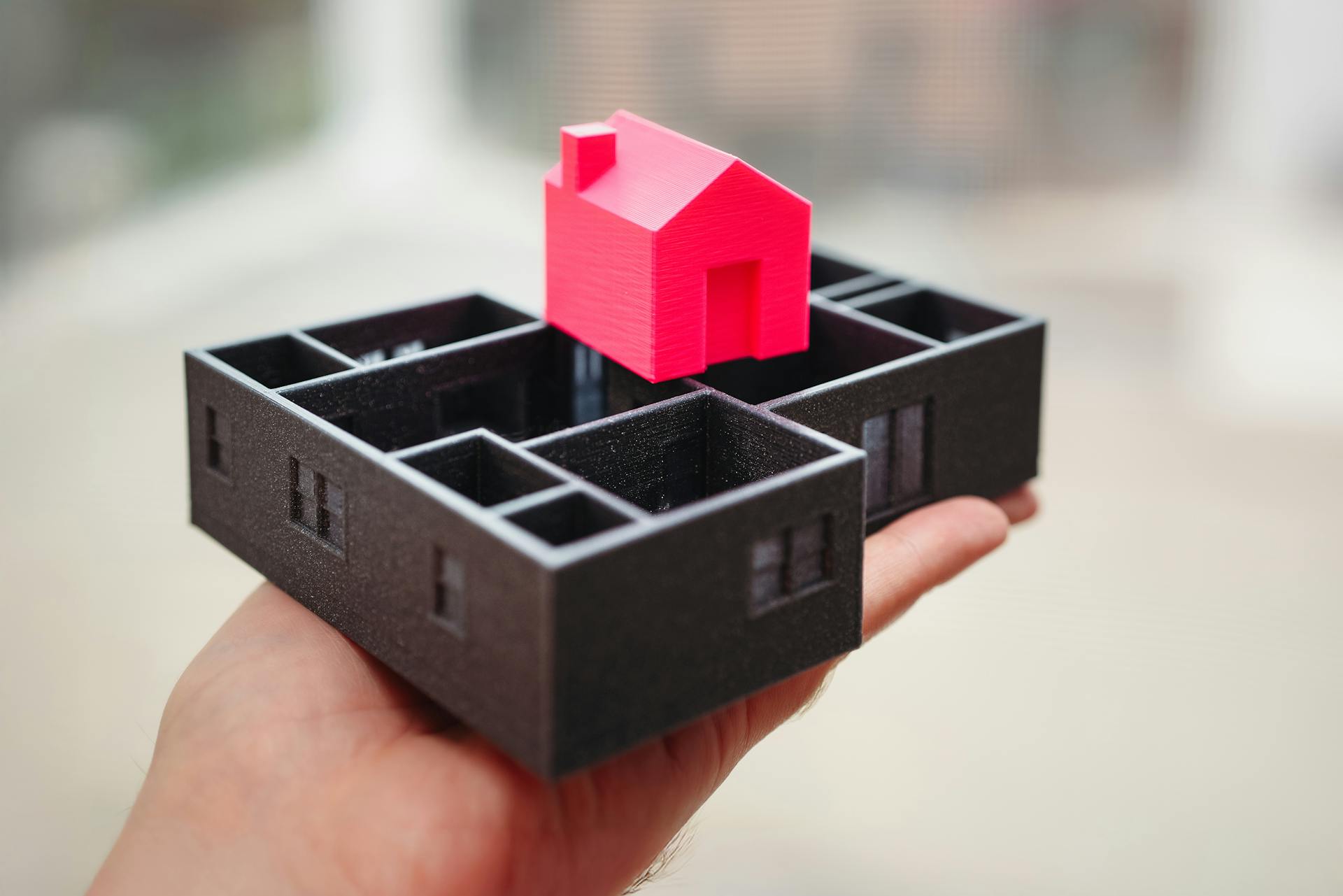

Industrial Metal 3D Printers can produce high-quality, large-scale metal parts with very little material waste. Sciaky's EBAM technology can produce parts up to 19' in length in a matter of days.

Expand your knowledge: Parts of a Check

The EBAM process can be used in any phase of the product life cycle, from rapid prototypes and production parts to repair and remanufacturing applications. This makes it a versatile tool for various industries.

Sciaky offers a range of EBAM systems, including the EBAM 300, EBAM 200, EBAM 150, EBAM 110, EBAM 53, and Custom systems. Each system has its own capabilities and configurations, from Mega-Scale to Medium-Scale.

Materials

When choosing materials for industrial metal 3D printing, weldable metals that are available in wire feedstock are ideal candidates.

Titanium and its alloys are great options, as they are commonly used in the industry and offer excellent strength-to-weight ratios.

Inconel 718 and 625 are also popular choices, known for their high temperature resistance and corrosion properties.

Tantalum, Tungsten, and Niobium are other metal candidates that can be used in wire feedstock form.

Stainless Steels, specifically the 300 series, are also suitable for industrial metal 3D printing.

On a similar theme: Can Western Union Wire Money to a Bank Account

2319 and 4043 Aluminum, as well as 4340 Steel, are also viable options for certain applications.

Zircalloy and 70-30 Copper Nickel/70-30 Nickel Copper are additional materials that can be used in wire feedstock form.

Here are some of the best materials for industrial metal 3D printing:

- Titanium and Titanium alloys

- Inconel 718, 625

- Tantalum

- Tungsten

- Niobium

- Stainless Steels (300 series)

- 2319, 4043 Aluminum

- 4340 Steel

- Zircalloy

- 70-30 Copper Nickel

- 70-30 Nickel Copper

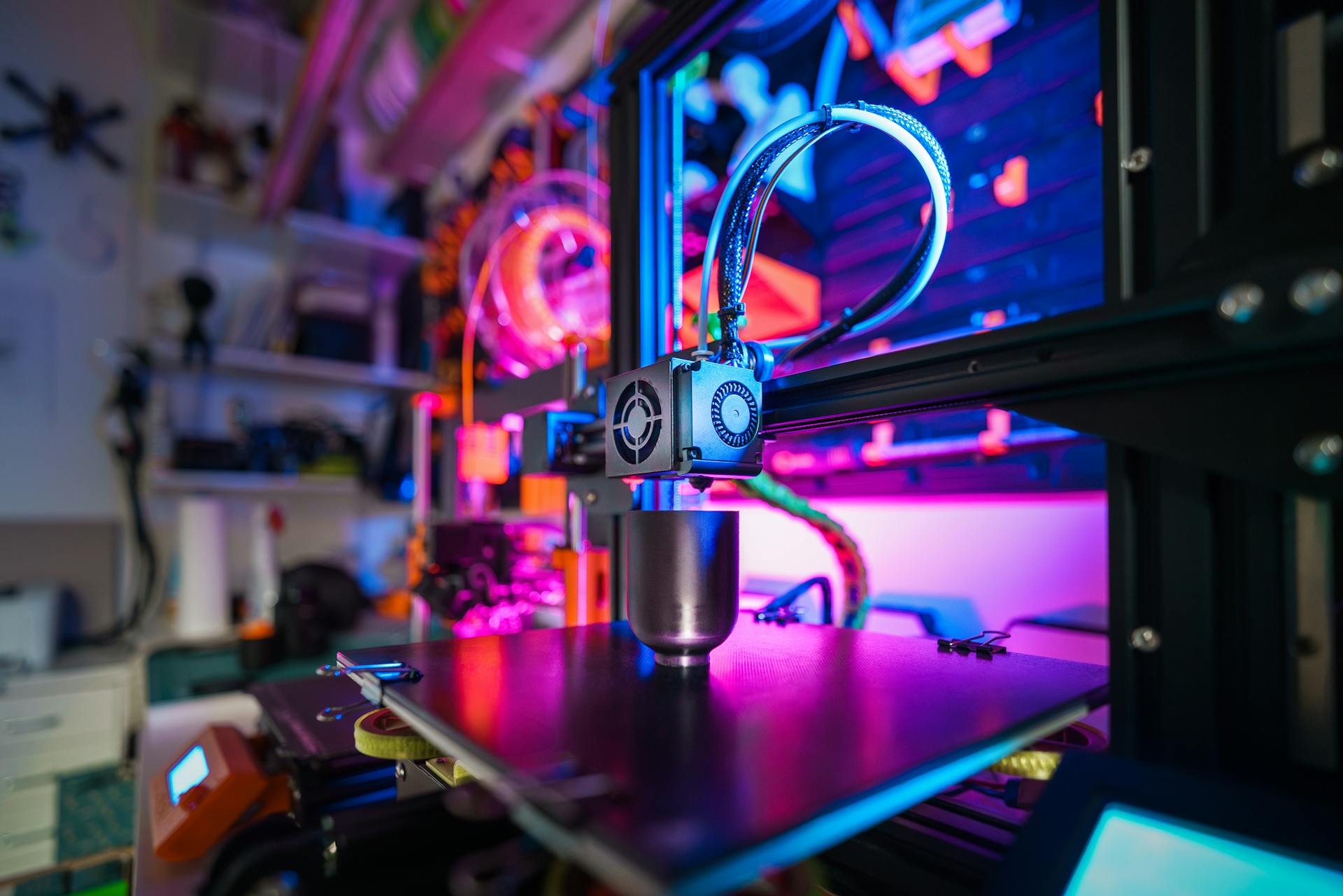

Turnkey Industrial Metal 3D Printers

Sciaky offers a range of turnkey industrial metal 3D printers for production parts, prototypes, and more.

Their EBAM 300, EBAM 200, EBAM 150, EBAM 110, and EBAM 53 systems all combine computer-aided design (CAD), electron beam directed energy deposition, and layer-additive processing.

These systems can deposit metal at rates of 7 to 40 lbs. (3.18 to 18.14 kg) per hour, making them the fastest and most efficient metal deposition process on the market.

EBAM systems are available in "Mega-Scale" (EBAM 300), Large-Scale (EBAM 200 & 150 Systems), and Medium-Scale (EBAM 110 Systems) configurations.

Here are the specific systems available:

- EBAM 300

- EBAM 200

- EBAM 150

- EBAM 110

- EBAM 53

- Custom

Each system has its own unique features and capabilities, and Sciaky also offers custom machine sizes to meet specific customer needs.

Sciaky's IRISS (Interlayer Realtime Imaging & Sensing System) is a patented Closed-Loop Control (CLC) technology that automates the EBAM process, ensuring consistent layer geometry, microstructure, and metal chemistry.

By using EBAM systems, you can achieve repeatable results with minimal finish machining required after the part reaches near-net shape.

The 110

The EBAM 110 System is a top-of-the-line industrial metal 3D printer that's capable of producing large-scale metal parts with incredible speed and precision.

This system boasts a massive chamber that measures 110 inches (2794 mm) on each side, allowing it to accommodate parts up to 106 inches (2692 mm) wide and 63 inches (1600 mm) high.

The EBAM 110 has a high-efficiency pumping system that can achieve a chamber hard vacuum of 1 x 10^-4 Torr.

It also features a powerful electron beam gun that can deposit metal at a rate of up to 40 pounds (18.14 kg) per hour.

The system's internal boom-mounted gun has high-resolution optics and a servo gun tilt axis, allowing for precise control over the metal deposition process.

The EBAM 110 also features X, Y, and Z servo axes with multiple part positioner options, making it easy to position and orient parts during the printing process.

For more insights, see: Do Banks Process Payments on Saturdays

Here are some key specifications of the EBAM 110 System:

- Chamber Dimensions: 110” (2794 mm) x 110” (2794 mm) x 110” (2794 mm)

- Work Envelope: 70” (1778 mm) wide x 47” (1194 mm) deep x 63” (1600 mm) high

- Nominal Part Envelope: 106” (2692 mm) wide x 47” (1194 mm) deep x 63” (1600 mm) high

- Power Level: up to 42 kW – 60 kV

- Closed-Loop Control (CLC) technology

The EBAM 110 System is a game-changer for industrial metal 3D printing, offering unparalleled speed, precision, and flexibility.

Data and Reporting

The E-BAM data logger can store an impressive 182 days of hourly concentration data, as well as hourly averaged data from up to eight other measurements.

This wealth of data is easily accessible and can be connected to other data recording systems via digital and analog outputs.

The E-BAM also automates particulate measurement by continuously sampling and reporting concentration data, with data records updated every minute.

Curious to learn more? Check out: Bofa Hacked

The 200

The 200 is a beast of a machine, with a massive work envelope that's perfect for large-scale projects. It measures 200" x 110" x 110" in chamber dimensions.

The build envelope is a whopping 160" wide, 47" deep, and 60" high, giving you plenty of space to work with. This is ideal for creating complex metal structures.

The 200 also boasts high efficiency pumping, reaching an ultimate vacuum pressure of 1x10^-5 Torr. This is crucial for maintaining a consistent and precise environment for your projects.

The power level of the 200 is quite impressive, reaching up to 42 kW-60 kV. This level of power is essential for high-speed and high-precision applications.

Here are some key specs of the 200:

- Chamber Dimensions: 200" (5080 mm) x 110" (2794 mm) x 110" (2794 mm)

- Build Envelope: 160" (4064 mm) wide x 47" (1194 mm) deep x 60" (1524 mm) high

- Power Level: up to 42 kW–60 kV

- Ultimate Vacuum Pressure: up to 1x10^-5 Torr

The 200's internal boom-mounted gun with high-resolution optics and servo gun tilt axis makes it a versatile machine for various applications.

Continuous Monitoring

Continuous monitoring is a game-changer for data collection and reporting.

The E-BAM automates particulate measurement by continuously sampling and reporting concentration data, with data records updated every minute.

This eliminates the hassle of filter collection and filter weighing, making the process much simpler and more efficient.

The E-BAM is a lightweight, portable instrument that can operate directly in hostile environments without an exterior enclosure.

It's easily installed in less than 15 minutes, making it a convenient option for many applications.

No other sampler matches the portability and flexibility of the E-BAM, making it a top choice for many industries.

Intriguing read: First Horizon Bank Credit Data Analyst

Reporting Modes

The E-BAM data logger is a powerful tool for storing and recording data. It can store over 182 days of hourly concentration data.

This is incredibly useful for long-term monitoring and analysis. You can easily track trends and patterns over an extended period.

The logger also allows for the connection of up to eight other measurements, providing a comprehensive view of the data. This makes it ideal for complex systems or multiple parameters.

Both digital and analog outputs are easily connected to other data recording systems, making it easy to integrate with existing infrastructure.

For more insights, see: Wells Fargo Online Banking down

Data Validation

Data validation is a crucial step in ensuring the accuracy and reliability of your data. It involves checking for errors and anomalies in your data.

The E-BAM system has selectable criteria for data validation, including deviation from a rolling average and high value excursions. These criteria help identify potential issues before they become major problems.

Should an error occur, it is entered into the error log with date, time, and type of error. This helps you track and address issues quickly.

For more insights, see: Bofa Connection Error

EBAM Systems and Solutions

Sciaky's EBAM systems bring value throughout the entire product life cycle, from pre-production to post-production. They enable you to create experimental metal prototypes faster than ever before.

EBAM systems can be used for various applications, including:

- Pre-production: Create experimental metal prototypes faster than ever before and get a leg up on your competition.

- Production: Additively manufacture metal parts (in your own facility) with significantly reduced machining time, material costs, and lead time compared to traditional subtractive manufacturing methods.

- Post-production: Repair or remanufacture damaged and obsolete metal parts on-site so you can extend various components’ service life.

Sciaky's EBAM systems are the world's most cost-effective process for producing near-net shape parts made from virtually any metal, including high-value metals like titanium and tantalum.

Overview of Systems

Sciaky's EBAM systems are designed to bring value throughout the entire product life cycle. They can be used for pre-production, production, and post-production.

The EBAM system was launched in 2009 with the goal of saving manufacturers time and money on the production of high-performance metallic structures. This goal has been achieved, making EBAM the world's most cost-effective process for producing near-net shape parts made from virtually any metal.

Here are some key features of the EBAM system:

- Automated and adaptive Real-Time Process Controls

- Automatic Process Variable Acquisition and Recording

The EBAM150 system is a specific example of Sciaky's EBAM technology. It has a large chamber and work envelope, allowing for the production of large parts.

Some key specifications of the EBAM150 system include:

- Chamber Dimensions: 150” (3810 mm) x 150” (3810 mm) x 120” (3048 mm)

- Work Envelope: 110” (2794 mm) wide x 62” (1575 mm) deep x 62” (1575 mm) high

- Nominal Part Envelope: 146” (3708 mm) wide x 62” (1575 mm) deep x 62” (1575 mm) high

The EBAM150 system also features advanced technologies such as high efficiency pumping, power levels up to 42 kW, and internal boom mounted guns.

Made in America. Deployed Globally

Sciaky is based in Chicago, IL, USA. Its welding systems and EBAM industrial 3d printing machines are distributed internationally.

You can find Sciaky's products in manufacturing plants around the world. Advanced research and development facilities also rely on their technology.

Their products are made in America, but you can get in touch with a local sales representative by clicking a link.

Custom

If you need a custom EBAM system, Sciaky can work with you to determine the right chamber size, work envelope, and CNC motion capabilities for your specific needs.

Sciaky's EBAM systems are highly customizable, and they can be tailored to fit a wide range of applications and industries.

The company offers a range of options for customizing their EBAM systems, including the ability to select from different chamber sizes and work envelopes.

This flexibility allows users to create a system that meets their unique needs and requirements.

Here are some of the custom options available for Sciaky's EBAM systems:

- Chamber size: Sciaky can work with you to determine the right chamber size for your application.

- Work envelope: The work envelope refers to the area within the chamber where the metal parts are manufactured.

- CNC motion capabilities: Sciaky's EBAM systems can be equipped with a range of CNC motion capabilities, including automatic process variable acquisition and recording.

By working with Sciaky to customize their EBAM system, users can create a solution that meets their specific needs and helps them achieve their goals.

Evidence-Based Asset Management

Evidence-Based Asset Management is a systematic approach that uses solid evidence to make informed decisions about physical assets. This approach is a significant shift from relying on experience, technician complaints, and OEM recommendations.

Historically, asset management decisions were based on intuition and guesswork. However, evidence-based asset management (EBAM) is the science of making the right decisions and optimizing asset management processes with the best available data.

Key asset management decisions should be based on solid evidence, not just common sense and expert judgment. This requires access to maintenance and financial data, which is critical for making informed decisions.

On a similar theme: Management of Bank Deposits

Accurately logging maintenance activities in a Computerized Maintenance Management System (CMMS) is essential for evidence-based asset management. This data provides the foundation for making data-driven decisions.

Evidence-based asset management is a logical approach to maximize the return on investment from physical assets. It provides direction on how to cost-effectively manage assets while maximizing availability.

In capital-intensive industries, evidence-based asset management is taking a fundamental shift from reactive to proactive maintenance. This approach can have a significant impact on operational performance and profitability.

Capital Equipment and Maintenance

Economic life is the expected period over which an asset is fit for purpose. This can be significantly shorter than the physical life of an asset.

The economic life of an asset occurs when the total cost of ownership is at a minimum. Organizations must ensure they have sufficient funds to purchase replacements at this point to reap potential savings.

Physical asset management is a systematic approach to operating, maintaining, upgrading, decommissioning, and renewing assets and infrastructure cost-effectively and to an acceptable standard. It can have a significant impact on the operational performance and profitability of an organization.

Curious to learn more? Check out: Cost of Funds Index

Evidence-based asset management (EBAM) is the science of making the right decisions and optimizing asset management processes with the best available data. Key asset decisions should be based on solid evidence.

In capital-intensive industries, asset management is shifting from reactive to proactive maintenance, with a focus on total cost of ownership. Evidence-based asset management is a logical approach to maximize the return on investment from physical assets.

The total cost of ownership should be a key consideration in capital equipment replacement decisions. This includes the cost of purchasing replacements, as well as other factors such as technical improvement on newer models.

Data-driven decisions are the most advantageous methodology for minimizing costs and maximizing the return on investment from physical assets. Accurately logging maintenance activities in a CMMS is critical for making evidence-based asset management decisions.

Resource requirements, including maintenance crews, machine shops, tooling, and contractor labor, should be right-sized to achieve productivity, system availability, and costs targets.

News and Updates

In recent news, Intuitive Machines successfully landed on the Moon using a part made with Sciaky EBAM technology. This achievement is a testament to the capabilities of EBAM in producing high-quality parts for space exploration.

Intuitive Machines used a Sciaky EBAM-made part in their lunar landing mission. This is a significant milestone for the company and for the EBAM technology.

EBAM, or Electron Beam Additive Manufacturing, is a type of 3D printing technology that uses an electron beam to melt and fuse metal powders together. This process allows for the creation of complex parts with high precision and accuracy.

The use of EBAM in space exploration has numerous benefits, including the ability to produce parts on demand and in remote locations. This can be especially useful for missions where transportation of parts may be limited.

Here are some key benefits of EBAM in space exploration:

- On-demand part production

- Remote location manufacturing

- High precision and accuracy

Sources

- https://www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology

- https://metone.com/products/e-bam/

- https://www.sciaky.com/additive-manufacturing/industrial-metal-3d-printers

- https://fiixsoftware.com/maintenance-strategies/evidence-based-asset-management/

- https://www.rbinternational.com/en/corporates/solutions/cash-management/ebam.html

Featured Images: pexels.com